Hybrid Machining

Hibiki Seiki was founded in 1967 in Shimonoseki, Japan. We specialize in high precision machining techniques that use both lathe and machining-centre technologies. With our main business in the semiconductor field, we are advancing into the aerospace, energy and medical sectors.

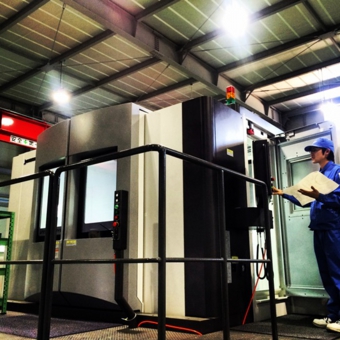

Facilities

We have both hybrid and 5 axis machining centres and we can machine directly from 3D data. We also use the "BLADE PRO&HOLOS" technology that allows us to directly measure and evaluate 3-dimensional parts.

Quality assurance.

Along with ISO9001 and ISO14001, we have the aerospace quality assurance JISQ9100. Our quality management system provides tractability throughout the company to ensure we meet all the quality assurance requirements.

Hard to machine materials

We have the experience and the know-how to machine materials from aluminium and stainless steel to titanium, copper, Inconel and Hastelloy. We can meet the needs of complex work such as ultra-thin walls, low rigidity and complex shapes. We can work together with your development team to increase the product quality and reduce the machining costs.

In-house training

We pride ourselves on our in-house training environment that allows our experienced craftsman to pass on their skills, knowledge and experience to the younger members of our team. This enables us to make sure that the same mistakes are never committed and our quality assurance along with our technological skills are always advancing.